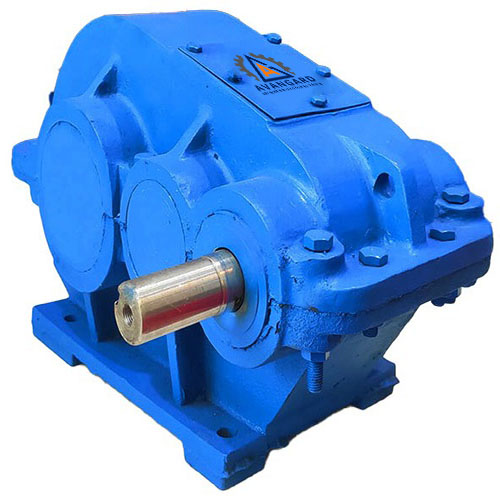

Frog Gearbox

Ready to send

Please contact the sales department for sending the list and bulk purchase of products.

Immediate shipment of the product is possible.

$0

Dear user, prices are being updated, please contact us.

What is a Frog Gearbox?

The Russian frog gearbox, also known as the Russian gearbox and Jolfa industrial gearbox, is one of the types of industrial gearboxes that is highly regarded in various industries due to its special design and superior performance. This gearbox, with its helical gears and engineered design, is capable of producing high power and torque. Its structure is such that it can perform well under continuous operation and heavy loads.

One of the distinguishing features of the frog gearbox is its unique design and large dimensions, allowing it to be used in heavy industries and large factories. Due to the use of powerful steel gears, this gearbox has a high load capacity and lower noise compared to other helical gearboxes, which increases efficiency and reduces the need for maintenance.

The applications of the frog gearbox are very extensive. This type of gearbox is especially used in heavy industries such as mining, sand washing machines, and large machinery. Also, due to its high quality and reliable strength, it is recognized in various industries as a credible and dependable option.

Moreover, the frog gearbox is easily available as stock in the market, allowing buyers to obtain this gearbox at more reasonable costs. In general, the frog gearbox, with its unique features and high capabilities, is considered one of the important options in the selection of industrial gearboxes for heavy and specialized applications.

Technical Specifications of the Russian Frog Gearbox

The Russian frog gearbox, recognized as one of the most advanced and durable types of industrial gearboxes, has specific technical features that make it ideal for heavy and industrial applications. Due to its engineered design and the use of high-quality materials, this gearbox is used in various industries. Here are some of the key technical specifications of this gearbox:

Structure and Design:

- Gears: The Russian frog gearbox uses helical gears with powerful steel teeth that help reduce noise and increase durability.

- Shafts: This gearbox has parallel shafts that help evenly distribute load and increase efficiency.

Torque and Power:

- Output Torque: Capable of producing high torques up to 5000 Nm or more, depending on the gearbox model and size.

- Transmittable Power: This gearbox can transmit different power levels, from 1 kW to 200 kW, making it suitable for a wide range of industrial applications.

Dimensions and Weight:

- Dimensions: The Russian frog gearbox, due to its specific design, has larger dimensions that allow for installation and use in heavy machinery and equipment.

- Weight: These gearboxes usually have more weight than other types because of the use of resistant materials and robust design.

Efficiency and Performance:

- Efficiency: The high efficiency of this gearbox reduces energy loss and improves overall system performance.

- Noise: The gear design is such that it produces less noise, contributing to increased user comfort.

Resistance and Durability:

- Load Resistance: The Russian frog gearbox, due to the use of steel gears and robust design, can withstand heavy loads and harsh operating conditions.

- Lifespan: The engineered design and use of high-quality materials help increase the gearbox lifespan.

Applications:

These gearboxes are widely used in heavy industries, mining machinery, sand washing equipment, and large factories.

| Type | Power (kW) | Weight | Input Shaft Diameter | Output Shaft Diameter |

| Russian Industrial Gearbox Type 100 | 0.5 | 20 | 16 | 28 |

| Russian Industrial Gearbox Type 150 | 1.5 | 25 | 22 | 30 |

| Russian Industrial Gearbox Type 200 | 2.2 | 40 | 22 | 38 |

| Russian Industrial Gearbox Type 250 | 3.5 | 90 | 30 | 55 |

| Russian Industrial Gearbox Type 350 | 7.5 | 160 | 40 | 55 |

| Russian Industrial Gearbox Type 400 | 11 | 270 | 40 | 80 |

| Russian Industrial Gearbox Type 500 | 16 | 320 | 50 | 80 |

| Russian Industrial Gearbox Type 650 | 20 | 800 | 60 | 110 |

Overall, the Russian frog gearbox, with its distinct technical specifications and robust design, is an ideal choice for industrial applications and large machinery that require high power and durability.

Advantages of Using Frog Gearbox in Various Industries

The frog gearbox is highly regarded in various industries due to its specific design and superior performance, offering numerous advantages. Its unique features make it a desirable choice in both heavy and general industries. Below are the main advantages of using a frog gearbox in various sectors:

High Power and Torque:

Thanks to the use of helical gears and engineered design, the frog gearbox can produce high torque. This feature makes it highly suitable for applications requiring significant power, such as mining industries and heavy machinery.

Long Lifespan and High Durability:

The robust design and use of high-quality materials grant the frog gearbox a longer lifespan and greater durability compared to other types of gearboxes. This advantage is especially important in large factories and heavy industries that need long-lasting equipment.

Noise and Vibration Reduction:

With its specific design and use of steel gears, this gearbox effectively reduces noise and vibrations. This feature helps improve working conditions and operator comfort, especially in industrial environments where noise and vibration can be problematic.

High Efficiency:

Due to its design and optimized structure, the frog gearbox offers high efficiency, helping to reduce energy loss and increase system performance. This feature is valuable in manufacturing industries and industrial processes that require high energy efficiency.

Capability to Bear Heavy Loads:

These gearboxes, with their robust design and powerful gears, are capable of withstanding heavy loads. This feature makes them suitable for applications like sand wash devices and rolling mills that need high power and strength.

Diverse Application:

Thanks to its power and special design, the frog gearbox is used across various industries, including mining, steel industries, and heavy machinery. This diversity of application indicates the high adaptability of this gearbox to different industrial conditions and needs.

In general, the benefits of using a frog gearbox include high power and torque, long lifespan and durability, noise and vibration reduction, high efficiency, and the ability to bear heavy loads. These features make this gearbox a very desirable option for various industrial applications and large machinery.

Guide to Choosing a Frog Gearbox:

Appropriately selecting a frog gearbox is crucial for ensuring optimal performance and high longevity of industrial equipment. Due to their unique design and high power, these gearboxes have widespread use across various industries. Here are key tips to help you choose the right frog gearbox:

- Determine Application Needs:

- Required Torque and Power: First, determine the amount of torque and power your system requires. Frog gearboxes can produce high torques, so make sure your chosen model meets your power needs.

- Type and Intensity of Load: The type of load on the gearbox (continuous load, impact load, or fluctuating load) should be defined. This information helps in selecting a gearbox with the suitable design.

- Review Technical Specifications:

- Dimensions and Weight: Choose a frog gearbox with appropriate dimensions based on space availability. Also, the gearbox weight can affect installation and stability.

- Speed and Transmission Ratio: The input and output speed, along with the gearbox’s transmission ratio, should align with your system’s requirements. Suitably designed frog gearboxes provide speed and torque adjustment.

- Quality and Durability:

- Materials and Construction: Pay attention to the quality of materials used in the gearbox’s construction. The frog gearbox should be made from durable, high-quality materials to endure pressure and heavy loads.

- Lifespan and Reliability: Reviewing specifications and quality tests indicating the gearbox’s lifespan and reliability can aid in proper selection.

- Brand and Manufacturer:

- Choose from Reputable Brands: Use well-known and reputable brands in the market. Brands with high experience and history generally offer higher quality products.

- Warranty and After-Sales Service: Ensure the purchased gearbox has a valid warranty and suitable after-sales service. This can prevent issues and additional costs in case of problems.

- Consult Specialists:

- Professional Consultation: Before purchasing, consulting specialists and experts in the field of frog gearboxes can help you choose the best option based on your specific needs. They can provide more precise guidance based on their knowledge and experience.

By adhering to these key points, you can choose the right frog gearbox for your industrial needs and benefit from its optimal performance and long lifespan.

Comparison of Frog Gearbox with Other Gearbox Types

The frog gearbox holds a special place among the various types of gearboxes due to its unique design and distinctive features. Here we compare the frog gearbox with other gearbox types to highlight its differences and advantages:

- Helical Gearbox:

- Design and Performance: Helical gearboxes, due to their use of helical gears, have smooth and low-noise operation. These gearboxes are suitable for applications requiring speed reduction and torque increase.

- Advantages and Disadvantages: Their main advantage is reduced vibration and noise. However, compared to the frog gearbox, they cannot produce as much power and torque, and they have less load capacity.

- Bevel Gearbox:

- Design and Performance: Bevel gearboxes are designed for transmitting power at a 90-degree angle and are typically used where direction change is required.

- Advantages and Disadvantages: These gearboxes can be installed in limited spaces due to their conical design. However, in comparison with the frog gearbox, their power and load-bearing capacity are less, and they may underperform in durability and lifespan.

- Worm Gearbox:

- Design and Performance: Worm gearboxes are designed for speed reduction and torque increase, and due to their special design, they have a self-locking capability.

- Advantages and Disadvantages: These gearboxes are suited for applications requiring speed reduction and high torque in small spaces. However, worm gearboxes usually have lower efficiency than frog gearboxes and cannot handle heavy loads effectively.

- Planetary Gearbox:

- Design and Performance: Planetary gearboxes, with their complex design incorporating sun, planetary, and ring gears, can produce very high torque and efficiency.

- Advantages and Disadvantages: These gearboxes have high efficiency and long lifespan, but due to their complex design and high costs, they may not be as suitable as frog gearboxes for some applications.

- Frog Gearbox:

- Design and Performance: With its unique design and use of helical gears, the frog gearbox effectively produces high power and torque. Its large dimensions and robust design allow it to handle heavy loads and reduce vibration and noise.

- Advantages and Disadvantages: Its main advantage is high power, durability, and the capability to handle heavy loads. Additionally, due to its special design, it is highly suitable for heavy industrial applications and high-pressure environments. Compared to other types of gearboxes, the frog gearbox is a highly desirable option for applications requiring high power and strength. However, its large dimensions may not be suitable for limited spaces.

In conclusion, choosing between a frog gearbox and other types of gearboxes depends on specific application needs, required power and torque, available space, and operational conditions. The frog gearbox, with its high power and durability, is suitable for heavy applications and high-pressure industrial environments, whereas other gearbox types may perform better in various fields with their unique features.

Price and Reputable Brands of Frog Gearheads in the Market

The frog gearbox, as one of the powerful and durable options among industrial gearboxes, is offered in the industrial equipment market with diverse prices and brands. Due to its special design and high power, these gearboxes are used in various industries such as mining, steel, and heavy machinery. Familiarity with reputable brands and existing prices can aid better decision-making when selecting a frog gearbox.

The price of the frog gearbox depends on several factors, including the brand, size, and technical features. Generally, the price of these gearboxes is relatively high due to their robust construction and powerful performance. Since frog gearboxes belong to the category of industrial gearboxes with high load-bearing capacity, their purchase cost is usually higher than lighter and less powerful gearboxes. However, for heavy applications requiring high torque, these costs are justified.

Reputable brands of frog gearboxes known for their quality in the market include:

- Shakhrin Sanat Sepahan Frog Gearbox:

One of the reputable brands with long-standing experience in producing high-quality industrial gearboxes with outstanding technical capabilities.

- Behkar Frog Gearbox:

This brand focuses on producing durable and resistant gearboxes for harsh conditions, making it a popular choice for various industries.

- TS Frog Gearbox:

Known for providing products with high performance and efficiency due to advanced technology and precise design.

- Toankar Frog Gearbox:

This brand is recognized and trusted in the market due to its focus on build quality and offering after-sales services.

- Flender Frog Gearbox:

The Flender brand focuses on providing durable gearboxes with a long lifespan, making it a suitable option for heavy industrial projects.

In selecting a frog gearbox, attention to quality and brand is very important. Purchasing from reputable Avangard stores and reviewing their warranty and after-sales service can assure you of a successful purchase. Also, consulting with Avangard commercial unit experts and thoroughly reviewing gearbox technical specifications can lead to an optimal and suitable choice for your specific needs.

Industrial Applications of Frog Gearbox: From Mines to Machinery

The frog gearbox, due to its unique design and high power, is used in a wide range of heavy industries and industrial applications. With its high power and durability, this gearbox can meet diverse needs under challenging working conditions and demanding industrial environments.

- Mines:

The frog gearbox in mines is highly practical due to its ability to endure heavy loads and harsh environmental conditions. These gearboxes are specifically used in mineral material transfer equipment, crushers, and mining conveyor belts. Their high power and reliability aid in performing operations with high volume and pressure.

- Steel Industry:

In steelmaking plants, the frog gearbox is used for power management and transmission in melting furnaces, rolling machines, and steel processing machinery. The ability of these gearboxes to function continuously under intense thermal and high-pressure conditions makes them an appropriate choice for this industry.

- Heavy Machinery:

Due to its exceptional power and durability, the frog gearbox is used in heavy machinery and construction equipment such as bulldozers, loaders, and industrial cranes. These gearboxes help effectively transfer power and enhance the performance of heavy devices.

- Petrochemical and Refinery Industries:

In industries where high power and precision equipment are required, the frog gearbox is used for power transmission in pumps, compressors, and processing systems. Its robust design and high pressure tolerance make these gearboxes suitable for such industrial environments.

- Processing Machinery:

The frog gearbox is also used in processing machinery such as packaging machines, production lines, and internal transport equipment within factories. High power and torque aid in optimizing the performance of these machines and increase production efficiency.

In conclusion, the frog gearbox, with its robust design and high power, plays a crucial role in various industries, from mining to heavy machinery. Its ability to withstand heavy loads and harsh conditions makes it an ideal option for challenging industrial applications.

Maintenance Tips for Frog Gearbox for Longer Lifespan

Due to its robust design and high power, the frog gearbox is an apt choice for heavy industrial applications. However, to ensure optimal performance and extend the useful life of these gearboxes, adhering to maintenance tips is essential. Here are some of the most critical tips for maintaining and preserving the frog gearbox:

- Regular Inspection:

Conducting periodic and regular inspections helps identify early problems and prevent serious damages. Inspections should include checking the condition of gears, shafts, bearings, and other key components. Checking oil and lubricants is also crucial.

- Lubricant Maintenance:

Lubricating oils play a vital role in reducing friction and preventing wear in the frog gearbox. Using high-quality lubricants and timely replacement maintain efficiency and reduce the likelihood of failure. Regularly checking and refreshing oil levels as needed is also necessary.

- Temperature Control:

Gearboxes are affected by temperature under various operating conditions. Regularly checking the cooling system and ensuring its proper function can prevent the gearbox from overheating and subsequent damages. Examine and address unusual temperatures as needed.

- Alignment and Balancing:

Ensuring proper shaft alignment and correct gear tuning prevents mechanical issues and extends gearbox lifespan. Misalignment or improper settings can cause uneven wear and premature failure.

- Contamination Prevention:

The frog gearbox should be kept in a clean, protected environment to prevent external contamination. Ingress of dust particles or chemicals can lead to rapid wear and component failure. Using filters and protective covers is recommended.

- Personnel Training and Awareness:

Training staff and technicians in proper maintenance and repair of the frog gearbox can help reduce human errors and extend device lifespan. Understanding correct operational and maintenance practices is crucial in maintaining gearbox efficiency.

- Timely Repairs:

In the event of failure signs or abnormal performance, prompt repairs should be initiated. Timely repairs and the use of quality spare parts can prevent further damage and higher costs.

By following these tips and conducting regular maintenance and repairs, the lifespan of the frog gearbox can be significantly extended and optimal performance ensured over time.

Frog Gearbox Price List

The price list of Russian industrial gearboxes, known for their high quality and outstanding durability in various industries, varies and depends on the type and features of the gearbox. These gearboxes are generally available in several models, including frog, worm, and planetary gearboxes, and their price is linked to factors such as power, load capacity, material, and manufacturer’s brand. For example, due to their high power and unique design, frog gearboxes are typically priced higher, while worm models may cost less due to their simpler structure. The price of these gearboxes can range from a few million Tomans to over twenty million Tomans. For price inquiries, contact the Avangard Holding sales experts.

| Row | Description | Price |

| 1 | Russian Industrial Gearbox PM Type 100 | Please call |

| 2 | Russian Industrial Gearbox PM Type 150 | Please call |

| 3 | Russian Industrial Gearbox PM Type 200 | Please call |

| 4 | Russian Industrial Gearbox PM Type 250 | Please call |

| 5 | Russian Industrial Gearbox PM Type 350 | Please call |

| 6 | Russian Industrial Gearbox PM Type 400 | Please call |

| 7 | Russian Industrial Gearbox PM Type 500 | Please call |

| 8 | Russian Industrial Gearbox PM Type 650 | Please call |

| 9 | Russian Industrial Gearbox PM Type 850 | Please call |

فارسی

فارسی

Reviews

There are no reviews yet.