Hydrocone Crusher Device

Ready to send

Please contact the sales department for sending the list and bulk purchase of products.

Immediate shipment of the product is possible.

$0

Dear user, prices are being updated, please contact us.

The Hydrocone or Cone Crusher is a type of crusher used to crush hard and heavy materials. This device is also known by various names such as cone crusher or hydrocone crusher. The main function of this device is based on hydraulic pressure, which compresses and crushes materials between two surfaces called mantle and concave.

The main structure of this device includes a fixed outer cone called the concave and a movable inner cone called the mantle. The materials brought in from above are directed into the space between the two cones through feeder arms. Then, the materials are compressed and crushed under hydraulic pressure between the two cones. The crushed materials are discharged from the bottom of the device.

This type of crusher is suitable for hard materials such as coal stones, limestone stones, iron stones, and iron ores and is used in mining and construction industries. Due to the use of hydraulic pressure, this device has high crushing power and efficiency. Also, easy adjustment of the output size and stable operation are among its main features.

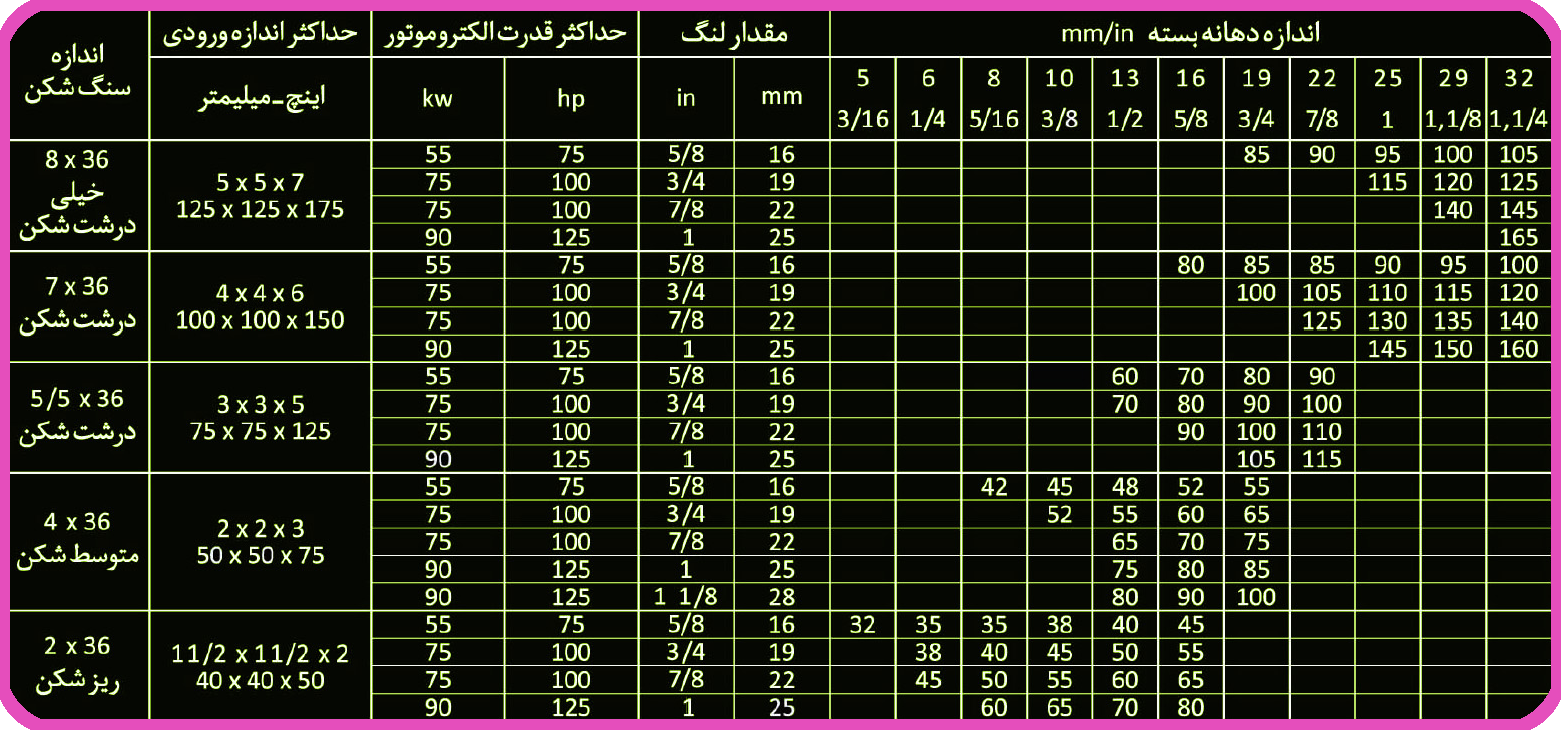

The hydrocone crusher is conical in shape and transforms extracted stones into flakes in the primary and secondary crushing stages in mines to make them usable. Hydrocones are produced in sizes 2-36, 4-36, 5-36, 5.5-36, 6.5-36, 8-36, named respectively as fine, medium, and coarse crushers. It is worth mentioning that the 45-inch size of the hydrocone device is also used in some mines.

Sale of Hydrocone Crusher

Sale of all types of hydrocone crushers with the best quality and most affordable price at Avangard Company, to order the product at the best price, contact the hydrocone crusher sales department experts.

Hydrocone Crusher

This mentioned device is among professional and modern crushers, nowadays it is considered one of the most widely used types of crushers due to its special features. This device can increase productions and, with similar input load to other crushers, receive a larger volume of gravel and sand. This device has automatic control of the output, which can be adjusted according to the input load to prevent damage.

Having these settings has made the maintenance and care of the hydrocone sand maker much simpler. The device requires less frequent servicing compared to other devices, resulting in lower wear and thus reduced costs. It can be used for many years without needing knowledge about replacing parts.

Another feature of the device is the capability for automatic lubrication, which helps in maintaining parts quality and reducing breakdowns. The maintenance and protection system has developed thanks to the automatic lubrication system, improving maintenance conditions without human involvement. The automatic and high-quality lubrication system of this device has also made it usable in mining areas of the country’s dry regions. To get the best performance from this device, keep it in suitable conditions and occasionally attend to its automatic lubrication.

General Specifications of the Hydrocone Device

- Every device consists of a structure that takes on the most performance and for the hydrocone includes:

- The device’s motor power is 90 kilowatts.

- Oil or water cooling system

- Lubricating oil volume 260 liters

- Hydraulic oil volume 80 liters

- Pinion shaft speed is 1083 rpm

- Total weight without chassis is 9000 kilograms

- Total weight with device chassis is 10000 kilograms

| Technical Specifications of Various Hydrocone Crushers | |||||||

| No. | Model | Maximum Input Dimensions (mm) | Output Material Dimensions (mm) | Production Capacity (t/h) | Motor Power (kw) | Machine Weight (ton) | Dimensions (LxWxH) (mm) |

| 1 | 36*2 Fine Crusher | 40 | 0-30 | 80 | 90 | 11 | 3000*1900*3800 |

| 2 | 36*4 Fine Crusher | 60 | 0-30 | 100 | 90 | 11 | 3000*1900*3800 |

| 3 | 36*5 Medium Crusher | 100 | 0-30 | 140 | 90 | 11 | 3000*1900*3800 |

| 4 | 36*7 Coarse Crusher | 160 | 0-50 | 160 | 90 | 11 | 3000*1900*3800 |

| 5 | 36*8 Coarse Crusher | 200 | 0-60 | 180 | 90 | 11 | 3000*1900*3800 |

Devices used in tough jobs like mining must have unique features to ensure long life and durability and to prevent constant repair or replacement of spare and consumable parts. The hydrocone crusher demonstrates exceptional capability in challenging working and environmental conditions, which we will mention below:

- Due to having a large opening, it has high capacity for load entry, making it suitable for large rock crushing.

- Used as primary and secondary crusher in aggregate sand mine crushing lines.

- Hydrocone has three lubrication systems.

- Due to its low weight, the hydrocone is easy to transport and install.

- High efficiency in breaking hard rocks.

- Shows high resistance during the stone crushing action due to robustness.

- Suitable for producing large volumes of sand and gravel.

- High performance with low maintenance cost.

- Resistant against abrasion due to the molybdenum-manganese steel material of its components.

- The feeding opening of this station can be designed and produced from 1 to 8 inches.

- Unique lubrication feature allowing use in hot and dry areas.

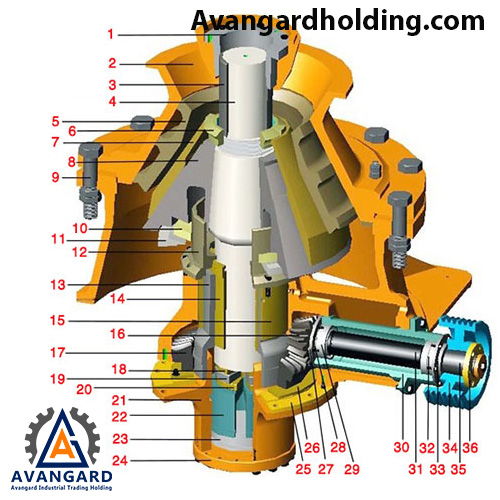

| Part Number | Part Name | Part Number | Part Name |

| 1 | Long Spider | 19 | Steel Plate |

| 2 | Top Shell | 20 | Flat Plate |

| 3 | Shaft Sleeve | 21 | Bowl |

| 4 | Main Shaft | 22 | Piston Bushing |

| 5 | Concave | 23 | Piston |

| 6 | Head Nut | 24 | Piston Plate |

| 7 | Mantle | 25 | Crown Wheel Ring |

| 8 | Head Center | 26 | Crown Wheel Flat Fiber |

| 9 | Main Bolt | 27 | Housing Cap |

| 10 | Feeder Duct | 28 | Bearing 22219 |

| 11 | Duct Ring | 29 | Housing Shell |

| 12 | Color Brush | 30 | Housing Shaft |

| 13 | Steel Bushing | 31 | Bearing 7219 |

| 14 | Eccentric Bushing | 32 | Housing Cap |

| 15 | Congregate Bushing | 33 | 46 cm Housing Pully |

| 16 | Pinion Gear | 34 | Pully |

| 17 | Crown Wheel Gear | 35 | Pully Iron Plate |

| 18 | Lens-like Plate | 36 | Cover |

Main Components of Hydrocone Crusher and Their Introduction

In general, crushers are used for crushing various types of stones. Some crushers are used for producing different types of sands, which we aim to introduce the internal components of the hydrocone crusher here.

| Part | Part Name | Part Number | Part Name |

| 1 | Congregate Bushing | 27 | Pinion Gear |

| 2 | Bottom Shell | 28 | Housing Cap |

| 3 | Housing Bearing | 29 | Dust Color |

| 4 | Housing Spacer | 30 | Flat Plate |

| 5 | O-ring | 31 | Shock Absorber |

| 6 | Top and Bottom Shell Spanner | 32 | Packing Plate |

| 7 | Steel Bushing | 33 | Chassis |

| 8 | Iron Pully Bushing | 34 | Main Shaft |

| 9 | Hydrolift Bushing | 35 | Housing Shaft |

| 10 | Eccentric Bushing | 36 | Duct Shade |

| 11 | Spider Bushing | 37 | Crown Wheel Flat Plate |

| 12 | Steel Pully Bushing | 38 | Steel Plate |

| 13 | Dynamo Pully | 39 | Spider Seal |

| 14 | Housing Pully | 40 | Spider Cap |

| 15 | Large Yoke | 41 | Concave |

| 16 | Small Yoke | 42 | Shaft Sleeve |

| 17 | Packing | 43 | Mantle |

| 18 | Housing Shell | 44 | Bowl |

| 19 | Top Shell | 45 | Duct Shade |

| 20 | Lubricant Tank and Jack | 46 | Hydrolift Base |

| 21 | Pot Bolt and Nut | 47 | Lens-like Plate |

| 22 | Bottom Shell Bolt and Nut | 48 | Flat Plate |

| 23 | Concave Bolt and Nut | 49 | Head Center |

| 24 | Piston | 50 | Pully Bushing Dish |

| 25 | Shaft Nut Ring | 51 | Shaft Nut |

| 26 | Crown Wheel Gear |

How a Hydrocone Works

In a hydrocone crusher, the material is crushed using the concave and mantle. There is a gap between the mantle and concave, and the size of this gap is adjusted by the main shaft. As a result, by changing the open gap between the mantle and concave, the size of stones and their discharge speed can be specified.

The cone or hydrocone sand maker is suitable for the crushing process of very large materials and rocks obtained from mines, transforming them into particular shapes and turning them into very tiny pieces called sand. Mainly used as a secondary crusher, the hydrocone functions in a way that the mantle and concave are placed very close together, and with the mantle’s rotation, the stones situated between these two parts are converted into very tiny pieces due to high pressure.

Minerals rotate inside the device in a circular way until they reach the appropriate and specified size. The fine gap occurring between these two parts is opened and closed by the main shaft’s rotation. However, it is crucial to note that the opening between the mantle and concave is adjustable and can be set relative to the position where the device is located and the stone sizes, to ensure the produced product is optimal and can be used effectively.

Moreover, by altering the device’s eccentricity, the passing speed and discharge of stones can be modified so that if the stones are very tough and strong, they are broken at a lower speed, and the stone-crushing or sand-making operation is carried out well. Adjusting the opening and gap is done by you, and it is easy but requires enough experience to know how much gap should be between the mantle and concave for each type of stone breakage and in every location.

Operators working with a sand maker should know that any error during the operation could lead to the loss of raw materials, causing significant damage. When purchasing mining and plant machinery, it’s crucial to consider the climatic conditions and device compatibility. It should be noted that the hydraulic and coolant oil is installed on the device chassis, and the electricity of the device can have both a fully automatic mode and a manual mode. This main control panel is responsible for the operation of the device.

| Model | Mantle | Concave | Top Shell | Maximum Inlet Dimension (mm) | Closed Opening (mm) | Total Production (ton/hour) | Fine Grain (ton/hour) |

| 2-36 | 2 | 2 | 4 | 50 | 8-10-13-19 | 60-65-70-80 | 42-45-49-56 |

| 4-36 | 4 | 4 | 4 | 100 | 13-16-19 | 80-90-100 | 52-58-65 |

| 5.5-36 | 4 | 5.5 | 5.5 | 140 | 19-22 | 105-115 | 68-69 |

| 7-36 | 4 | 7 | 7 | 175 | 25-29-32 | 145-150-160 | 87-90-96 |

| 8-36 | 4 | 8 | 8 | 200 | 32 | 165 | 82 |

Hydrocone Crusher Prices

The price of hydrocone crushers varies based on the type and capacity of the device and can be in different sizes: 2-36, 4-36, 5-36, 5.5-36, 6.5-36, 8-36, or according to specific customer preferences and price fluctuations. For ordering, buying, selling, and producing the desired crusher, contact our experts at Avangard Company.

Apologies, prices are being updated; please contact Avangard’s sales unit for purchase price inquiries..

| No. | Description | Price in Toman |

| 1 | Hydrocone Crusher Price 2-36 | Contact Us |

| 2 | Hydrocone Crusher Price 4-36 | Contact Us |

| 3 | Hydrocone Crusher Price 5-36 | Contact Us |

| 4 | Hydrocone Crusher Price 5.5-36 | Contact Us |

| 5 | Hydrocone Crusher Price 6.5-36 | Contact Us |

| 6 | Hydrocone Crusher Price 8-36 | Contact Us |

فارسی

فارسی

Reviews

There are no reviews yet.